Unless you are running a pure cross-dock model in your DC, the wave process has likely been a pain point more than once for you or your client. A proper wave strategy will ensure you are keeping the DC’s staff fully utilized and are able to hit your target volumes. A suboptimal wave strategy forces you to constantly shuffle resources to different processing areas due to inconsistent product flow and eats away at your productivity.

In this post we’ll explore a few different problems that often plague DC’s waving and provide insight on how to identify if these problems exist at your DC.

Configuration – Setting you up for success

Industry leading WMS providers offer highly configurable waving tools. Most clients only use a fraction of the available waving capabilities. While the wave configuration may have been set up to meet your initial business needs when you went live, it might not be set up to handle your current needs in the most efficient manner.

Most DC wave planners are clever and are able to bridge or hide gaps that emerge with a shift in a DC’s needs by using different configuration options that they are familiar with. The changes made by these operators are often not the best way to meet the changing needs of the building. In some cases, these changes can cause negative performance impacts such as: suboptimal cubing results, poor fill rates, inefficient task creation leading to a decline in units per hour, and a host of other problems.

If you have seen a decline or volatility in the any of the areas mentioned above, it may be due to your waves not being configured to best meet your business needs. WMS experts, who have experience across numerous business flows are able to quickly identify what changes could be made in order to rectify the issues caused by your changing business requirements.

Visibility – What you don’t know can hurt you

Most out of the box WMS solutions don’t provide the visibility required to track the work generated by the wave as it flows through your building or give the DC insight to how your outbound performance changes over time. Proper visibility is key to ensuring you are waving in a way that drives outbound efficiency. If you have adequate reporting, you should be able to answer the following questions without digging through multiple screens or resorting SQL or Access tools:

- What work needs to be done in order to close out a wave?

- How much work is in your order pool by processing area?

- How many open tasks are in each area?

- Do you have enough available trailer space to meet today’s volume?

- What are your units per hour (UPH) by processing area?

- How many shorted units do you have by processing area?

- What percentage of picks require replenishments by processing area?

These are just a few questions that can help identify reporting gaps. Once you are able to answer these, and other questions like these, you can determine if your wave strategy needs refining in order to optimize performance in each processing area. The WMS experts at Bricz can help you answer these questions and determine if there is room for improvement in your different processing areas.

Performance – Don’t let your system slow you down

At some point in time, almost every DC has experienced a wave that takes longer than expected. These occasional, long-running waves do not necessarily constitute a true performance issue. However, if you are continuing to see waves take longer than expected on a weekly basis, a deep dive on wave performance should be performed.

So where do you start when you think you are having performance issues? The first thing you should do is revisit the original performance expectations and compare those to the current day performance. You’ll want to compare both your standard sized waves and peak volume waves to the original expectations. If you are still within the bounds of the initial expectation, you’ll need to have a discussion on whether or not the performance expectations need revision.

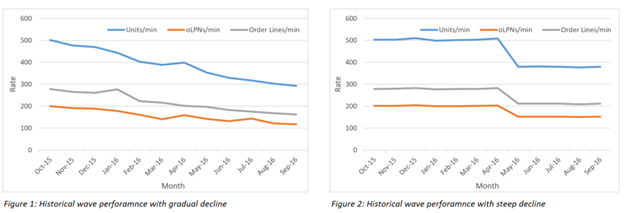

Next if you are storing historical waving data you will also want to plot wave performance in units, order lines, and oLPNs per minute over time. Below are two different examples of historical wave performance plotted over time.

If your historical wave performance graph looks similar to Figure 1, your wave performance degradation is likely due to a gradual change in process, order pool profile, or a system processing capabilities due to overall increase in volume. If your graph looks more like Figure 2, the change in performance is most likely tied to a configuration change, or code change. Compare current configuration to lower lifecycle environments and analyze code changes made close to the date the performance decrease occurred in order to identify if either of these is the case.

What Next?

The topics discussed in the above sections should help you get a jump start on figuring out if you have room to improve your waving process. The Supply Chain Leaders at Bricz can help further analyze each of these areas more to make sure that you are waving in the most optimal manner.