As the world continues to define what the “new normal” looks like nearly three years after a global pandemic, companies are also revisiting and redefining what “normal” even looks like in their own supply chains.

It is no secret that the COVID-19 outbreak shook supply chains world-wide and exposed major weaknesses that were left ignored for far too long. In a study conducted by EY, 72% of companies noted that the pandemic negatively impacted their supply chain operations. Some industries were impacted more than others: of the automotive companies surveyed, 97% reported negative impacts on their supply chain operation.

The rise of Industry 4.0, characterized by advancements in automation, cloud connectivity, algorithmic models, and data utilization, has shifted the focus towards utilizing technology and upgrading infrastructure to address supply chain challenges. In the post-COVID era, many companies have set their sights on incorporating “smarter” systems that can seamlessly communicate with one another and provide more efficient insights. This technological shift informs many of the supply chain trends we’re seeing as we move farther into the new year.

Here are some key supply chain trends to watch for in 2023:

Artificial Intelligence and Machine Learning

The integration of predictive analytics has revolutionized decision-making in various industries, and supply chains are no exception. With the use of Artificial Intelligence software, companies now have the capability to transform vast amounts of disjointed data into actionable insights for management teams.

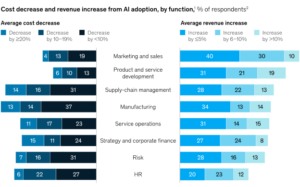

According to a study conducted by McKinsey & Company, the implementation of AI can decrease overall costs and increase overall revenue, even when taking into account the cost of implementation.

Machine learning models are also becoming more flexible, allowing them to adapt to real-time issues as they arise. Companies such as SAS and Clari are already offering beta models for forecasting. However, this technology extends into the heart of the supply chain – warehouses. Many of our strategic partners that offer Tier 1 WMS solutions like Manhattan, Koerber, and Blue Yonder have already started focused efforts for AI implementation into their existing software.

Data

The use of data at every stage of the supply chain, from forecasting to optimizing warehouse efficiency, is crucial for making informed decisions. By effectively analyzing data, companies can identify and address problems in their supply chain operations before they escalate. However, many companies face challenges in collecting real-time, accurate information, such as disconnected host systems, inaccurate reporting, and outdated processes. This significantly hinders their ability to effectively manage and improve their supply chain operations.

According to study by the Data Warehousing Institute, poor data quality incurs significant financial losses for companies, with an estimated loss of around $600 billion annually. This lack of visibility into the supply chain also made it challenging to address specific issues brought on by the COVID-19 pandemic. In light of this, many companies are now focusing on enhancing inter-system communication and streamlining data collection processes in 2023 as a solution to these problems.

Software Enhancements

With the increased strain on supply chain operations in recent years, advancements in software solutions have become a vital concern for supply chain executives. While software remains a fundamental aspect of modern supply chains, many current systems have become a hindrance rather than a benefit. Supply chain teams are constrained to operate within the limitations of their current systems, rather than fully capitalizing on their potential advantages. Inventory optimization, robotics integration, and real-time analytics as well as predictive analytics and Control Towers are just a few of the new tools companies can leverage when they upgrade their existing software.

According to a study conducted by Blue Yonder, 83% of companies have already started to invest in their supply chain infrastructure – 86% of which have heavily invested in technology. However, this is just the beginning – with new software solutions offered every day, the options to find a software that best meets unique conditions are complicated and confusing.

Are you unsure of which of these trends align best with your business needs? Are you struggling to know where to begin with modernizing your systems and data reporting? Our team of supply chain technology experts at info@bricz.com is here to help you navigate your options, develop solutions, and build a more resilient supply chain in 2023.

Contributor: Sana Ansari, Supply Chain Consultant and Bricz