In my experience working on inventory optimization with multiple companies, the Pareto or 80/20 rule has been commonly followed for inventory classification. Organizations have dedicated resources and budget to focus on the top 20% of their products to drive 80% of their revenue. In doing so, they neglected the remainder 80% of products. For a lot of companies these lower volume products constitute a substantial part of their revenues, and they need to invest in inventory management strategies to not end up with low margins and decreased profitability.

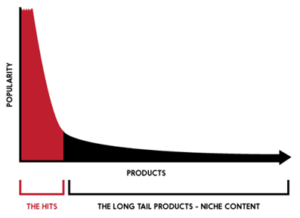

Before we dive deeper into ways to tackle these lower volume SKUs, let’s define the term Long Tail and how it plays a role in this discussion. Long Tail conceptually refers to the extended downward slope of a unit sales curve. When illustrated graphically, the curve depicts a “long tail” as demand wanes toward zero. In plain language, the long tail comprises the products that have low sales volumes.

Maintaining a diverse product portfolio, introduction of new products and dealing with seasonal products are key factors that lead to Long Tail. Adding more SKUs to diversify a portfolio leads to a reduction in average sales per SKU thereby creating more slow movers. For example: having multiple varieties of orange juice such as no/some/high pulp, with/without calcium and with/without vitamin D gives customers a variety to choose from but at the same time can potentially lead from a high-volume SKU to multiple low volume SKUs. Moreover, the retail industry is particularly susceptible to Long Tail due to its many points of sales that result in disaggregated demand and thus more SKU-locations. The issue was only exacerbated by the omnichannel fulfillment trend.

Managing Long Tail has been a big challenge for several companies. They are inherently difficult to plan due to their intermittent and unpredictable demand patterns. Traditional methods of inventory planning that rely on a stable demand distribution without considering variability are not a good fit for tackling Long Tail. From my interaction with various clients, I notice that companies tend to wrongly predict Long Tail demand and either overstock or understock their products. This leads to a negative financial impact due to working capital being tied up in slow movers or lost sales.

More and more companies are recognizing that Long Tails can be good for the bottom line if they are tackled properly. Incorporating automated Multi-Echelon Inventory Optimization tools is critical to managing the complexities of Long Tail. These tools take into account their inherent demand and use advanced technologies like machine learning to provide an optimal inventory mix across different nodes of the network. They provide the order size recommendations by using advanced Safety Stock calculations. They consider the unit cost, demand, lead time, stocking strategy and the order interval amongst other factors. This, in turn, leads to better fill rates which in turn transpires into better service levels. An oversimplifying example can be purchasing a lot of parts due to lower unit prices to benefit from economies of scale might be counterproductive as it will lead accumulation of inventory for years leading to stock obsolescence.

Managing your Long Tail is not an easy task. Calling on the right expertise to manage your diverse portfolio of SKUs can lead to substantial revenue increases and cost savings. If you are dealing with Long Tail problems and are thinking of ignoring them or simply killing your Long Tail, DON’T! Reach out to us!

Bricz, a leading global supply chain solutions provider, emphasizes connectivity while providing compelling results and minimizing potential issues. We are focused on helping retailers and other consumer-centric industries optimize their supply chain as we have described above. Interested in learning more about our services and how we can help elevate your supply chain? Reach out today at info@bricz.com to connect with one of our subject matter experts to get started.

Contributor: Sahiti Kalapala, Senior Supply Chain Consultant at Bricz