While the thought of UAVs (unmanned aerial vehicles), or autonomous drones is typically associated with revolutionary drone delivery from companies like Amazon and Walmart, there is another functionality for drones in companies supply chains. Warehouse operations has many needs for fast and reliable movements outside of final mile delivery. The days of walking the warehouse and paper picking are over, and many of the inventory control methods are found to be obsolete in today’s times. Here’s how drones are improving the first half of the supply chain process- warehouse logistics.

Inventory can be managed by using drone technology. Tracking has become easier, and a company can know where their inventory is at any given moment. Not only are these methods of inventory control easier and more efficient, but they are also safer and more cost effective. The reason for this is that companies minimize waste by reducing travel of people going around a warehouse scanning barcodes and counting items. Drones can perform these tasks automatically, while also decreasing the risk of handling items stored at taller heights and freeing up humans to perform more value-added tasks.

Most companies are opting for a cloud connected drone fleet. This will allow the system to automatically update with inventory levels no matter how small or large the fleet of drones is. This is powered by intelligent automation, and operators that focus on supervisory, efficiency and regulatory aspects. A single drone can help a distribution network replace entire inventory control teams.

Warehouses also have many rules and regulations for what the work area must look like to have a safe and efficient shift. For this reason, companies are required to have teams do thorough inspections to ensure work readiness. However, companies could use drone technology to inspect areas of the warehouse everywhere. Many warehouses are over one million square feet, so this would significantly decrease time needed as well as labor used. This also helps increase safety on a site, as any potential hazards can be assessed using drone visualization.

Security in a warehouse is also a big concern for many companies. There are many variables when deciding how and when to staff on site guards and how to equip them to defend, monitor and protect themselves and other assets in a warehouse. While using drones, companies would be able to inspect potential security threats using AI-enabled software to recognize threats, and then alert the proper authorities.

The cost of drone technology can vary from firm to firm, depending on product, drone quality, and support system. The average drone is expected to cost around $1,000. While drones are a costly experiment, the overall ROI is a factor that propels many companies to pull the trigger on autonomous aircraft for inventory management. The reason for this is that it lowers overhead costs and staffing expenditures.

When companies’ facilities need to transport goods within their own building, it is referred to as intralogistics. Intralogistics often will consistently deliver spare parts, tools, and missing components for maintenance requirements and customer orders. There are pre-established flight paths for these drones to be able to fly in the warehouse without damaging itself or product. One upside of this type of operation is that there are not any FAA approvals to fly a drone completely indoors.

There are multiple stakeholders in this new industry of warehouse drones. Most drone technology companies are currently only focused on inventory management in the warehouse operations side of drone use. As technology progresses, we have seen other drone vendors begin to help retailers and warehouses automate drone operations and bring them to scale with their bandwidth. Some of which are also in the spaces of drone delivery, inspections, and security and surveillance.

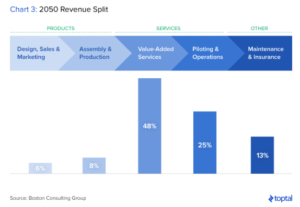

Travel time in warehouses also accounts for over half of picking times, as well as other warehouse functions that drones would help reduce those times. A study referenced below shows the total allocation that is being used for drones in the warehouse, and their individual function. Value added services, such as picking and cycle counts, make up an overwhelming majority.

As UAV technology continues to improve, there are sure to be more functions that drones will be able to take on, including more robust picking abilities and potentially utilizing hybrid technologies.

By 2026, the global warehouse automation market is estimated to surpass $30 billion US Dollars. Drones are going to play a large role in this. The improvements in safety, operational efficiency, and cost reduction will propel autonomous vehicles to the forefront of inventory control.

If you are interested in learning about our robotics solutions and offerings or would like to create a business case for robotics in your DC, please reach out to info@bricz.com to hear back from one of our subject matter experts.

Contributor: Daniel Bondi, Supply Chain Consultant at Bricz

Sources:

How Autonomous Drones Are Revolutionizing Warehouse Logistics (uavcoach.com)

How Drones are Accelerating in the Warehousing and Logistics Industry (analyticsinsight.net)

Drones for warehouse inventory management – Argon & Co (argonandco.com)

The Drone Market and Industry Trends | Toptal

50 warehouse automation stats you should know – 6 River Systems

Warehouse Drones for Inventory Management (agvnetwork.com)

(3) Drones in Warehousing: 10 Success Factors to Consider | LinkedIn