Your organization has invested in a software implementation or upgrade to cater to increasing demands, to increase efficiency, to reduce costs, and transform or streamline your supply chain. What good is an implementation if you don’t realize your supply chain potential after spending so much time and money?

A largescale implementation project, such as WMS implementation, has so many moving parts. Often, the implementation has members from different teams and sometimes different organizations. Each of these team members have their own areas of responsibilities and focus; however, it is important to work towards a common goal — The Big Picture.

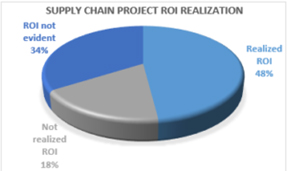

According to a study conducted by DC Velocity, only 48% of the projects realize ROI. Supply chain leaders with a vision for strategic transformation stay focused on realizing ROI. While there is a necessity to adapt and progress with tactical engagements, leaders keep the emphasis on accomplishing long term goals and ROI by establishing the right set up for success.

One Team – Create an environment that promotes a “One Team” approach. The customer, software vendor, and consultants need to be aware of the overarching goals and will need to execute to achieve the common goal.

Design – Collaborate for detailed business requirements documentation and ensure the solution design process is global and flexible. Engage all the right personnel during design to ensure a comprehensive design.

Development – Focus on flexibility, future proofing, and anticipate the changes that may be around the corner.

SMEs – Engage subject matter experts that can bridge the gap between legacy systems and the future state.

Technology – Ensure the technology and architecture will support the operational requirements and allow for some flexibility in throughput and volumes.

Ensure to include the appropriate personnel during design. An industrial engineer will be able to develop effective slotting strategies with the right information during design. An architect may be able to develop mobile support strategies for labor management. Engaging the right personnel and having data points and metrics ahead of solution design will allow the software vendor to provide the best options for your specific need.

For example, the location layout and zoning must be compatible with how the system is configured to work. Failing to do so might result in having to redo some or all parts of the layout.

Experts with prior insight on more than one area of the project can come in handy to bridge the gap between teams. An industrial engineer with WMS product knowledge or a software developer with significant exposure to warehouse operations can share unique perspectives during design and in various phases of the engagement.

With the right planning, setup, and resources, WMS implementations can be highly successful!